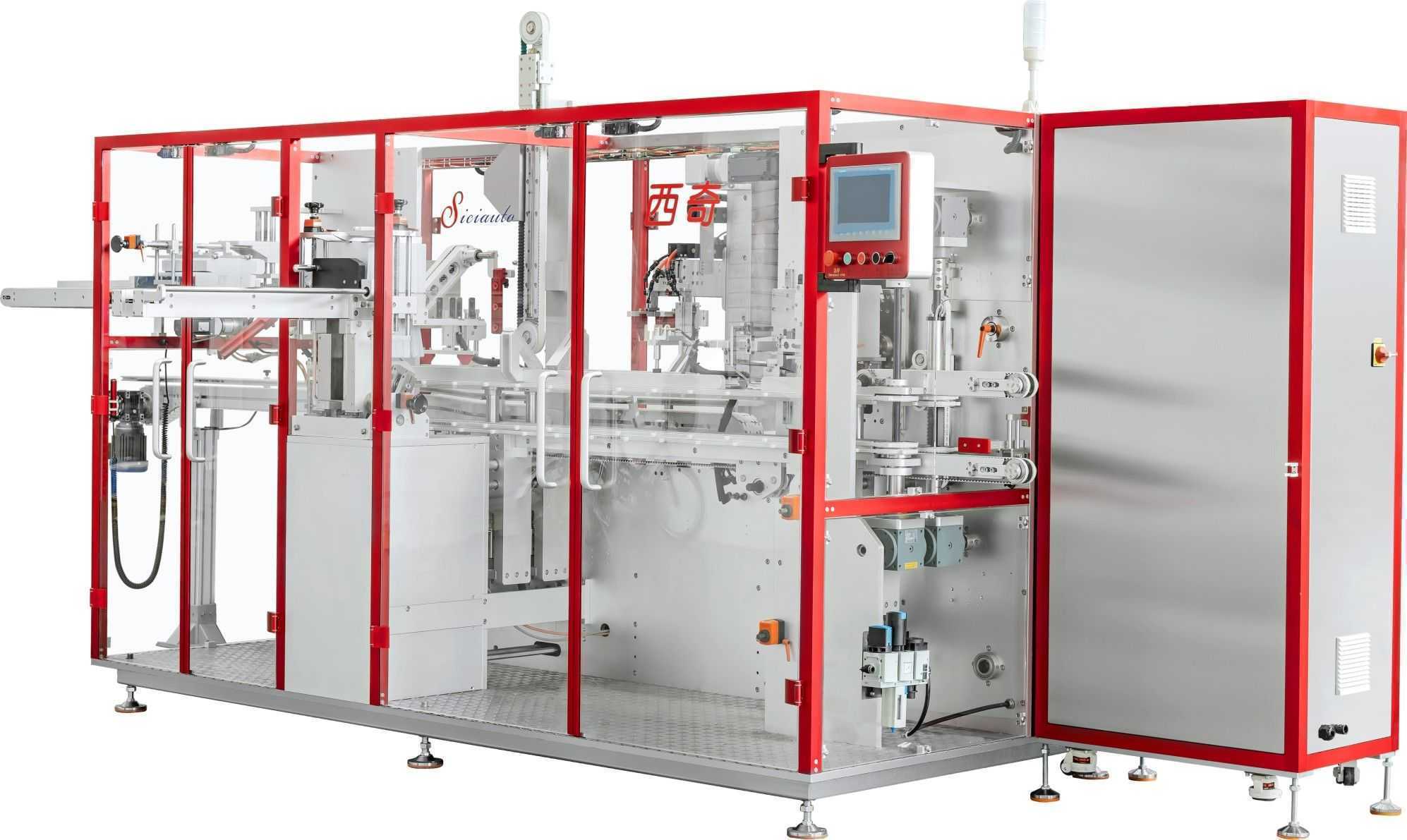

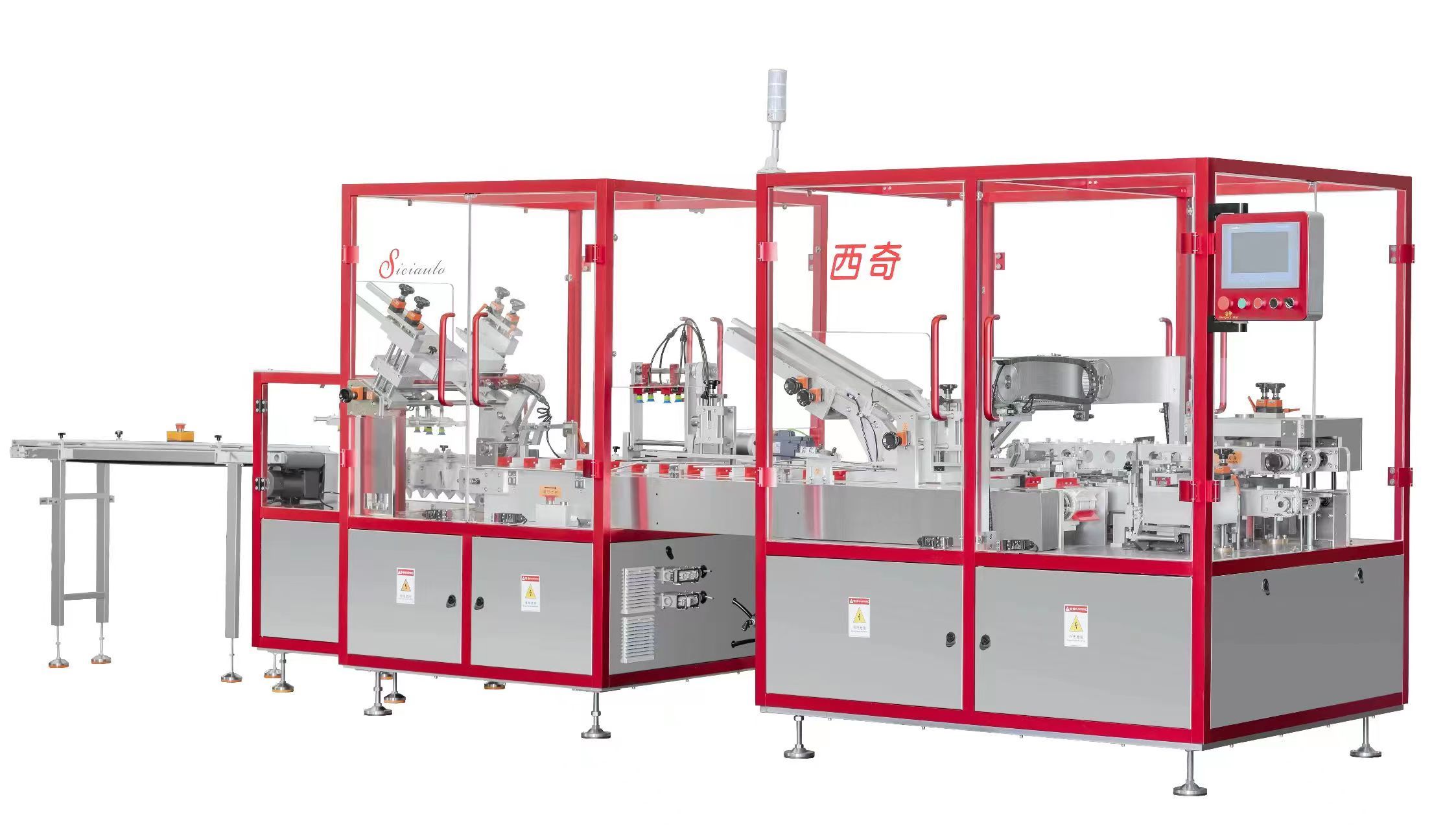

The vertical cartoning machine is a cartoning machine to pack product into carton box by top loading, specialized for vertically oriented products.

A vertical cartoning machine, also known as a vertical cartoner, is a type of packaging machinery used in the pharmaceutical, food, and consumer goods industries. It is designed to automate the process of erecting, loading, and closing cartons or boxes for the packaging of various products.

Vertical cartoning machines are particularly suitable for packaging products that are vertically oriented, such as bottles, tubes, pouches, and similar items. They are versatile and can handle a wide range of carton sizes and shapes, depending on the specific machine's design and capabilities.

These machines offer several advantages, including increased packaging speed, improved accuracy, reduced labor costs, and enhanced product protection. They are often integrated into larger packaging lines, working in conjunction with other machines such as fillers, labelers, and cappers, to create a fully automated packaging system.

It's worth noting that there are various types of cartoning machines, including horizontal cartoners and wrap-around cartoners, each designed for specific packaging requirements. The vertical cartoning machine, as described above, is specialized for vertically oriented products.

| Model | XQ-TZ-160 |

| Maximum Speed | 60-80 pcs/min |

| Normal working speed | 50-70 pcs/min |

| Carton size range (L*W'H) | Max 50×80×220mm; Min 50*50*45mm |

| Power supply | 380W/ 50Hz |

| Main Power | 3.0kW |

| Compressed air | 0.6MPa |

| Air Consumption | 3m³/h |

| Machine Dimension | 5300×2150×2350mm |

| Machine Weight | 1600Kg |

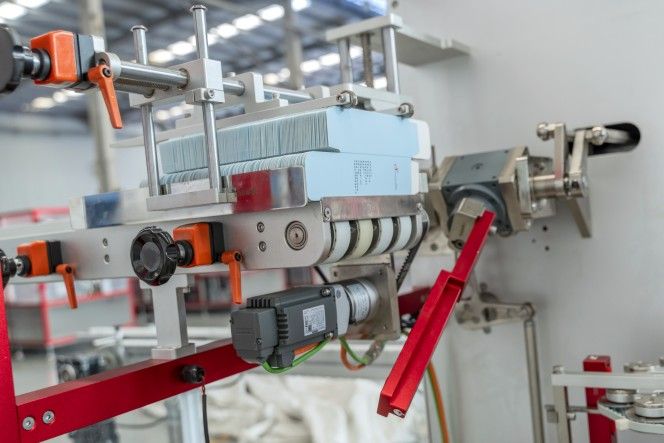

Machine Principle

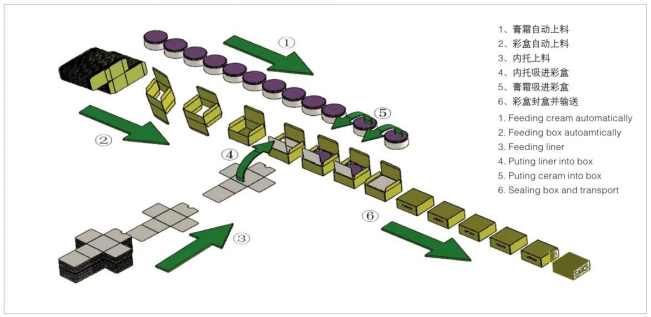

The machine receives flat, pre-glued carton blanks and uses mechanical or pneumatic systems to fold and shape them into a three-dimensional carton. The carton is then held in place while the product is loaded into it. The product may be manually placed into the carton or fed automatically from a production line. Once the product is loaded, the machine seals or closes the carton using various methods such as gluing, tucking, or applying adhesive tape.

Features & Functions

◆Different types of configuration can produce makeup, lotion and emulsion, cream, cleaner, mask and other products cartoning.

◆No additional cost is required to change the specifications of the whole machine.

◆Vertical packing method doesn't change the shape of the cream material.

◆It can be used with or without liner.

◆Easy to switch specifications, will cost about 20-40mins.

◆Pure mechanical design, stable and efficient.

◆Optional configuration of various automatic feeding modes for different products.

◆Leaflet feeding deivce is optional.

PRODUCT SAMPLES

PACKAGING & SHIPPING

PACKAGING

Film wrapped inside and standard export carton packing outside.

SHIPPING

30 working days after confirming order and receiving the deposit.

Specific delivery date should be decided according to production season and order quantity.