- Home

- About Us

- Workflow

- Projects

- Customer Feedback

- Private Policy

- Products

- Overwrapping Machine

- Cartoning Machine

- Case Packer

- Labeling Machine

- Shrink Wrapping Machine

- Case Erector

- Case Sealer

- Check Weigher

- Strapping Machine

- All-side Ironing Machine

- Tea Bag Packing Machine

- Packaging Materials

- Pillow Type Packing Machine

- Filling And Capping Machine

- Tube Sealing Machine

- Solutions

What is the difference between L sealer and Side sealer?2021-07-21What is the difference between L sealer and Side sealer?

For packaging equipment-those who are familiar with shrinking machines know that both L sealer and Side sealer can be used with assembly lines to realize unmanned operation. However, the price of the two types shrink wrapping machine has nearly doubled difference. What is the difference between L sealer and Side sealer, and why the price is doubled. Here’s the answers for everyone:

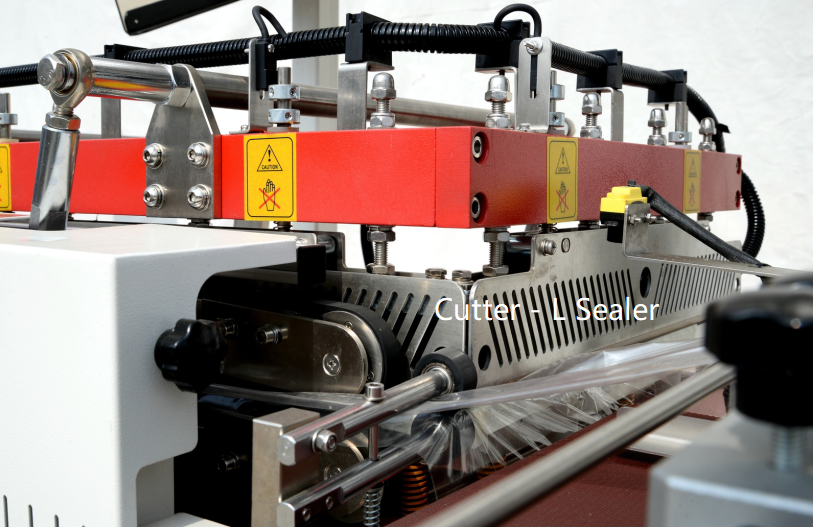

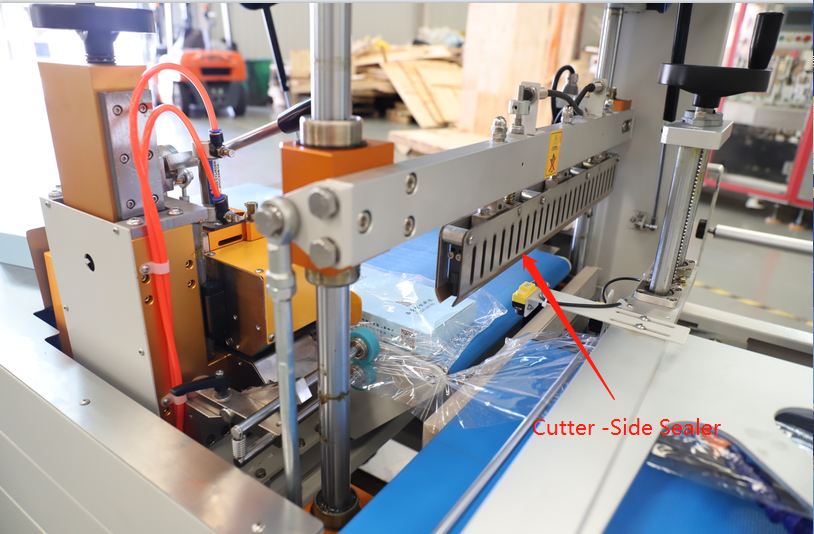

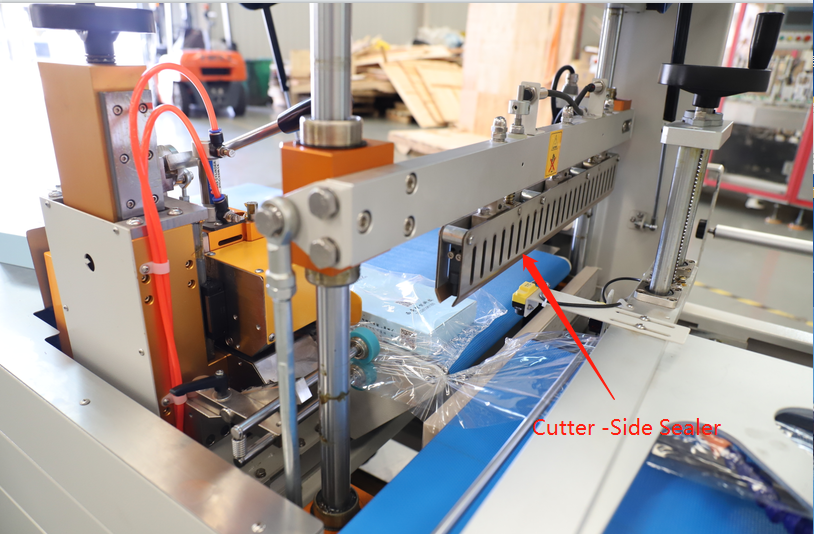

1. The cutter is different: the cutter of L sealer is L-shaped, and the whole cutter is in motion during the sealing and cutting. The Side sealer has a horizontal knife for the packaging, and the side knife side is always in the sealing and cutting state. Therefore, the two cutting methods are different from the principle of sealing and cutting.

2. Different structure: Although the appearance of the L sealer is similar to that of the side sealer. But the structure of the two devices is completely different. In particular, the two operating principles of the cutter are far apart.

3. Different efficiency: This is also the fundamental difference between the L sealer and the side sealer. The work efficiency of the two is completely different. The working efficiency of the L-type shrink wrapping machine is about 25 packs per minute. The working efficiency of the side sealer shrink wrapping machine can reach 40 packs or more.

4. The packing size is different; the L sealer has a large limitation on the size of the packaged product because the sealing knife is fixed. However, because the side knife is always in the sealing and cutting state of the side sealer, there is no limit on the length of the product in theory for side sealer.

About us- Tel: +86-510- 85868879

- E-mail: sales@siciauto.com

- Address: No.132-4, Rongyu Road, Xishan Economic Development Zone, Wuxi City, Jiangsu Province, China.

- SUPPLIER

- PROJECTS

Wuxi Sici Auto Co., Ltd. Boxmedia