- Home

- About Us

- Workflow

- Projects

- Customer Feedback

- Private Policy

- Products

- Overwrapping Machine

- Cartoning Machine

- Case Packer

- Labeling Machine

- Shrink Wrapping Machine

- Case Erector

- Case Sealer

- Check Weigher

- Strapping Machine

- All-side Ironing Machine

- Tea Bag Packing Machine

- Packaging Materials

- Pillow Type Packing Machine

- Filling And Capping Machine

- Tube Sealing Machine

- Solutions

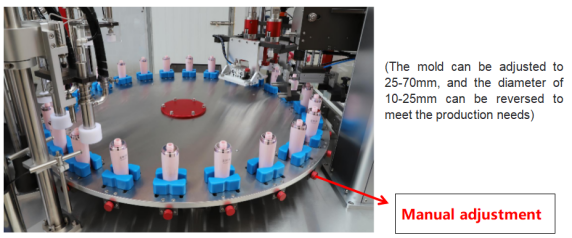

What Is Rotary Disc Filling Machine?2023-09-24Rotary disc filling machine is composed of blowing and sucking, filling, capping, pressing outer cover, clamping and so on. The equipment adopts the manual putting bottle, automatic blowing, automatic filling, manual putting outer cap, automatic screwing outer cap, manual putting outer cover, automatic screwing outer cover, automatic rotation, automatic clamping mode. The device has a small footprint, and is equipped with adjustable bottle mold suitable for a variety of products.

Rotary disc filling machine can put bottle or tube by hand, also can equip automatic feeding bottle/tube device to make it achieve full automatic. It’s widely used for perfume, toner, emulsion and cream.

The Machine Features

1. Rotary disc filling machine using the latest innovative design of adjustable type bottle mould, automatic production for a variety of packaging material, do not need to change the mould. (Adjustable without tools)

2. Equip 2 sets of Japan original installation import anion generator and electrostatic dust removal system.

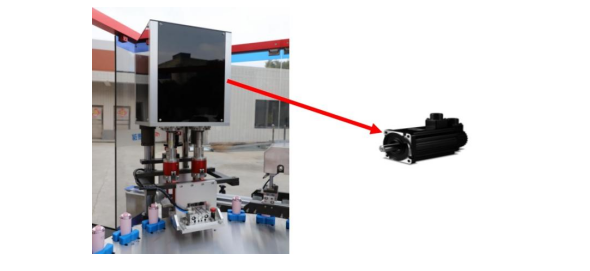

3. Servo motor filling, high filling precision; The filling speed can be adjusted to achieve different filling speeds for different materials, effectively solving the problem of foaming materials

4. The new anti-collision design of bottle mouth is adopted to avoid the problems of sprinkling, bottle mouth damage and bottle head breaking caused by the impact of the filling head on the bottle mouth to be filled during the filling process.

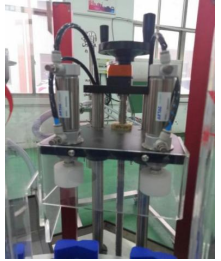

5. The whole machine is equipped with two sets of filling system, filling system USES cart type design, all valves connection parts disassembly is very convenient for quick loading institutions, convenient customer fast for production.

6. Using pneumatic to pressure inside or outside cover

7. With servo motor screw cap, torsion can be adjusted, and does not hurt the cap.

8. With manipulator grasping finished products to packaging, gripper head size is adjustable.

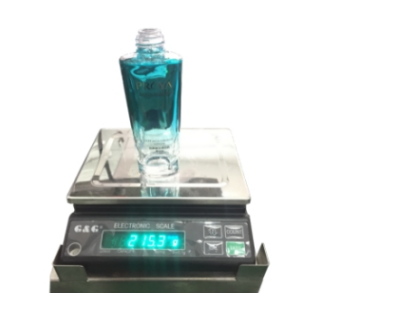

9. Equipped with automatic weighing feedback system, automatic filling dose adjustment (used for debugging when adjusting the dose, the online inspection, the normal operation can take spot check when filling accuracy).

10. The whole machine is equipped with two sets of filling systems. During production change, the used filling system can be disassembled directly from the main machine and pushed directly into the cleaning room for cleaning. The spare filling system can be connected to the main machine for production.

The equipment feed system can be directly connected to the customer's mobile storage tank or the feed line can be inserted into the material barrel for filling. The connecting parts between the feed piston cylinder and the cylinder are quick-mounting mechanism, which is very convenient to disassemble.

11. Equipment filling valve using our custom foodstuff valve, valve, simple in structure, convenient in disassemble very clean no dead Angle, all the pipes adopt health level fast loading pipeline and quick release coupling, in full compliance with the GMP standard; The valve, pipe disassembly and cleaning are very convenient.

12. Equipped with two sets trolley (the trolley contains 1 set of feed pump, piston cylinder, filling pipe, container, valves, etc.), can be realized easily change production within 15 minutes.

Welcome to visit www.siciauto.com to learn more about rotary disc filling machine

Or visit our Youtube Channel to learn more cases by https://www.youtube.com/c/SICIAUTO.

About us- Tel: +86-510- 85868879

- E-mail: sales@siciauto.com

- Address: No.132-4, Rongyu Road, Xishan Economic Development Zone, Wuxi City, Jiangsu Province, China.

- SUPPLIER

- PROJECTS

Wuxi Sici Auto Co., Ltd. Boxmedia