- Home

- About Us

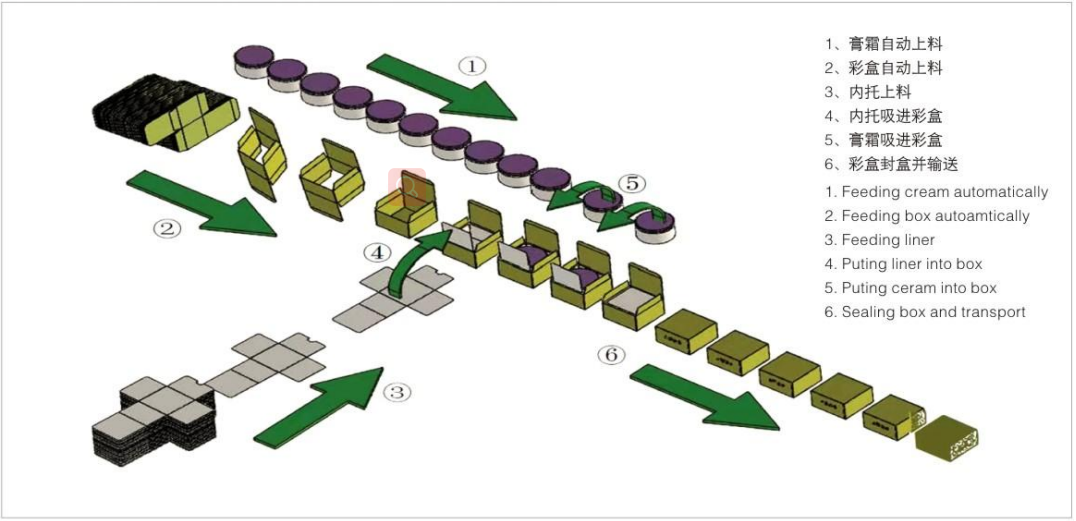

- Workflow

- Projects

- Customer Feedback

- Private Policy

- Products

- Overwrapping Machine

- Cartoning Machine

- Case Packer

- Labeling Machine

- Shrink Wrapping Machine

- Case Erector

- Case Sealer

- Check Weigher

- Strapping Machine

- All-side Ironing Machine

- Tea Bag Packing Machine

- Packaging Materials

- Pillow Type Packing Machine

- Filling And Capping Machine

- Tube Sealing Machine

- Solutions

The Type of Cartoners2023-04-07Cartoning machines, also known as cartoners, are used to package products in cartons or containers. These machines come in various types and configurations, each suited for a specific packaging requirement. In this article, we will discuss the different types of cartoners.

Vertical Cartoners

Vertical cartoners are used for packaging products in a standing position, such as bottles, jars, or cans. These machines are ideal for products that need to be filled from the top. The product is loaded into the carton from the top, and the cartoner seals the carton using glue or other adhesives. Vertical cartoners are suitable for high-speed packaging applications and can handle a wide range of carton sizes.

Horizontal cartoners are used for packaging products in a lying position, such as tubes, sachets, or blister packs. These machines are ideal for products that need to be filled from the side. The product is loaded into the carton from the side, and the cartoner seals the carton using glue or other adhesives. Horizontal cartoners are suitable for high-speed packaging applications and can handle a wide range of carton sizes.

End-load cartoners are used for packaging products that require loading from the end of the carton. These machines are ideal for products that are longer or taller than the carton itself. The product is loaded into the carton from the end, and the cartoner seals the carton using glue or other adhesives. End-load cartoners are suitable for high-speed packaging applications and can handle a wide range of carton sizes.

Side-load cartoners are used for packaging products that require loading from the side of the carton. These machines are ideal for products that are wider than the carton itself. The product is loaded into the carton from the side, and the cartoner seals the carton using glue or other adhesives. Side-load cartoners are suitable for high-speed packaging applications and can handle a wide range of carton sizes.

Wrap-around cartoners are used for packaging products that require a wrap-around carton, such as bottles, cans, or jars. The carton is formed around the product, and the cartoner seals the carton using glue or other adhesives. Wrap-around cartoners are suitable for high-speed packaging applications and can handle a wide range of carton sizes.

Tray formers are used for creating a tray from a flat piece of cardboard or corrugated material. These machines are ideal for products that require a tray for packaging, such as fruit, vegetables, or frozen foods. The tray is formed around the product, and the tray former seals the tray using glue or other adhesives.

In conclusion, cartoning machines come in various types and configurations, each suited for a specific packaging requirement. The type of cartoner required depends on the product being packaged, the packaging speed required, and the size and shape of the carton. By choosing the right type of cartoning machine, businesses can optimize their packaging process, reduce wastage, and improve productivity.

More videos pls refer to our Youtube channel:

https://www.youtube.com/channel/UCRNJ_rvH5vfrNUPrc7ppxsw

About us- Tel: +86-510- 85868879

- E-mail: sales@siciauto.com

- Address: No.132-4, Rongyu Road, Xishan Economic Development Zone, Wuxi City, Jiangsu Province, China.

- SUPPLIER

- PROJECTS

Wuxi Sici Auto Co., Ltd. Boxmedia