- Home

- About Us

- Workflow

- Projects

- Customer Feedback

- Private Policy

- Products

- Overwrapping Machine

- Cartoning Machine

- Case Packer

- Labeling Machine

- Shrink Wrapping Machine

- Case Erector

- Case Sealer

- Check Weigher

- Strapping Machine

- All-side Ironing Machine

- Tea Bag Packing Machine

- Packaging Materials

- Pillow Type Packing Machine

- Filling And Capping Machine

- Tube Sealing Machine

- Solutions

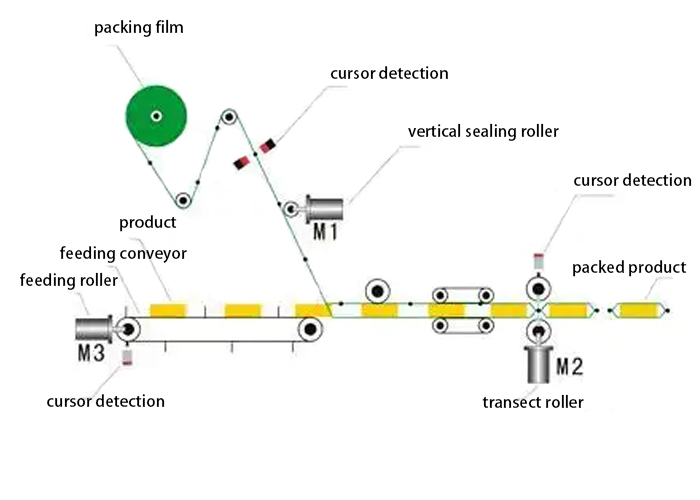

How to Choose A Suitable Pillow Type Packing Machine2023-06-16Pillow type packing machine often referred to as horizontal packaging, it is a high-yield and high-efficiency automation equipment. Horizontal packaging with a single film roll three welding: two cross welding and one longitudinal welding. This packaging equipment is widely used in the food industry, such as stem and leaf vegetables in fresh food, frozen semi-finished products, simple outer packaging plastic sealing can see a typical example of pillow packaging. But how to choose a suitable pillow type packing machine? Let’s talk about it in the following points.

1. Suitability for cladding

a. Customers can choose the right pillow type packing machine according to the characteristics of their products. Now, there are many models for different materials on the market, which requires buyers to look for in the market, and with a direction in this area of choice will be a lot of convenience, because you can comprehensive consideration to meet their own requirements. If there is no corresponding model on the market, the customer needs to choose according to the nature of the product, such as the product is easy to fall slag or the shape is very loose, you should choose the lower film, because the lower film machine enters the packaging stage, the middle seal is located above the material, so the residue will not fall into the machine during the packaging process, but also to ensure the integrity of the packaging;

b. It is strongly recommended that customers take their own products and packaging film to test the package in the selection of the machine, because this can be based on the product after packaging molding to determine whether to achieve their desired effect, of course, the best way can also be the customer only to provide materials, by the pillow packaging machine manufacturer to help choose packaging materials, so it may be easier to meet customer requirements.

2. The stability of the packaging machine itself

This should be a problem that all customers need to consider when choosing the packaging machine, of course, there is no technical problem of how to choose, and customers need to test the machine more when choosing, because the machine does not have a large strength and long time operation at the manufacturer, and does not reflect the stability of the machine.3. Packaging speed

Packaging speed is a very important factor that customers need to consider when choosing a machine, when the customer determines the expected output, it also determines the speed of the pillow type packing machine. After all, the customer is based on production capacity, because the packaging method of the packaging machine on the current market determines the packaging speed, such as the packaging speed of the reciprocating packaging machine is relatively slow, and the rotary packaging machine is relatively fast. In addition, the speed of the pillow type packing machine is also related to the size of the packaging material and the components added. If the machine is also equipped with parts with functions such as inflation, the speed will not be very high, which needs special attention.

4. Scalability

Scalability is determined by customers' future planning and product diversity. At the beginning, many customers may choose some low-end equipment, such as ordinary motors or variable frequency electric machines, due to capital and scale limitations, but the future development is unmanned and automated factories. It is necessary to choose some mid-end servo machines and relatively strong machine manufacturers when purchasing equipment as much as possible, which can make it easier and more reliable for the machine to become a production line or upgrade the machine. If the strength of the machine manufacturer is weak or the research and development ability is not enough, the model has not changed and upgraded for many years. Then customers should not expect their machines to be too much improved on the basis of the original.

5. Operability and safety

Because the current packaging machine also needs operators to adjust and install film rolls, including some necessary settings and adjustments to the machine when packaging different materials, which requires the packaging machine to carry out these work easier and simpler the better, not only saves time, but also does not require special training operators, can save a lot of manpower and material resources, Production safety is advocated by every company, and for the safety of operators, packaging equipment should carry out some necessary protection.

6. Packaging materials

Due to the different packaging materials, the environment of the machine is not the same, the selection of equipment to take the production environment into account at the same time the purchase of technical parameters, in order to prevent the machine can not meet the customer's packaging requirements.

About us- Tel: +86-510- 85868879

- E-mail: sales@siciauto.com

- Address: No.132-4, Rongyu Road, Xishan Economic Development Zone, Wuxi City, Jiangsu Province, China.

- SUPPLIER

- PROJECTS

Wuxi Sici Auto Co., Ltd. Boxmedia