- Home

- About Us

- Workflow

- Projects

- Customer Feedback

- Private Policy

- Products

- Overwrapping Machine

- Cartoning Machine

- Case Packer

- Labeling Machine

- Shrink Wrapping Machine

- Case Erector

- Case Sealer

- Check Weigher

- Strapping Machine

- All-side Ironing Machine

- Tea Bag Packing Machine

- Packaging Materials

- Pillow Type Packing Machine

- Filling And Capping Machine

- Tube Sealing Machine

- Solutions

What is Intelligent Manufacturing and Personalized Customization?2020-04-02Intelligent Manufacturing (IM) is a human-machine integrated intelligent system composed of intelligent machines and human experts. It can perform intelligent activities such as analysis, reasoning, judgment, conception, and decision-making during the manufacturing process. Through the cooperation of humans and intelligent machines, we will expand, extend and partially replace the brain work of human experts in the manufacturing process. It extends manufacturing automation to flexibility, agility and intelligence.

In the industrial age, the greatest progress from Industry 1.0 (mechanization), Industry 2.0 (industrialization), Industry 3.0 (automation) to Industry 4.0 (intelligence) is driven by software and data. We call "Industry 4.0" the digital industry era. From data to big data, chips and software give machines comparable to human intelligence. In the fiercely competitive Chinese market, reducing costs and improving efficiency has become a common pursuit of the industry. Industry 4.0 allows design, configuration, ordering, planning, manufacturing, and operation Such links can take into account the specific needs of individuals and customers, and may still be profitable in the case of one-time production and low output (even single-piece production).

For example, personalized clothing customization, the machine can scan the 3D data of the human body, and the software system converts the size and shape of the fabric according to the clothing style and cutting style, which needs to consider the fabric properties (shrinkage, elasticity, etc.), sewing process, etc. The operation requires big data support. In the subsequent production process of clothing, in addition to automated equipment and production lines, it also requires task instructions from big data such as capacity matching, process guidance, material distribution, and quality control. Intelligent manufacturing passes the workshop-style personalized customization The software system and automation equipment have been upgraded to industrial scale production, and the system has accumulated big data that exceeds the experience of various craftsmen in a self-learning way.

Let's conceive of a cosmetics company for personalized customization. First, we need to establish a database of cosmetic formulas (the corresponding relationship between formulas and skin care health): whitening of class A raw materials, oil control of class B raw materials, and class C raw materials to improve cell vitality ..., then According to customer information: skin characteristics (photoelectric measurement), care preferences, use environment (climate, temperature, humidity, etc.), cultural differences, etc., generate cosmetic formulas suitable for each customer based on big data, and then customize production.

As mentioned above, intelligent manufacturing is not the improvement of an enterprise's single ability, but a leap in the enterprise's comprehensive capabilities. Only hardware, software, big data, cloud computing and Internet integration can truly realize intelligentization. Intelligent manufacturing is the basis of personalized customization. Customization is a breakthrough for intelligent manufacturing to extend the market and improve efficiency. After all, for most companies, the market is more troublesome than the production capacity.

The requirements of personalized customization for intelligent manufacturing are flexible manufacturing and agile manufacturing. On the one hand, agile manufacturing is the flexible response capacity of production capacity, that is, the small batch production capacity of machinery and equipment; on the other hand, it is agile and precise in the supply chain Responsiveness is the ability of the system to adapt to changes in the external environment.

Intelligent manufacturing relies on software and data to drive business flow and machine equipment operation, and collect relevant data. The intelligent manufacturing system can not only continuously enrich the knowledge base in practice, but also have self-learning functions, as well as collect and understand environmental information and its own Information, and the ability to analyze, judge, and plan their own behavior, and be able to quickly adjust equipment production lines in the production process, but reduce production efficiency and increase production costs, and respond quickly to rapidly changing market demands and market progress.

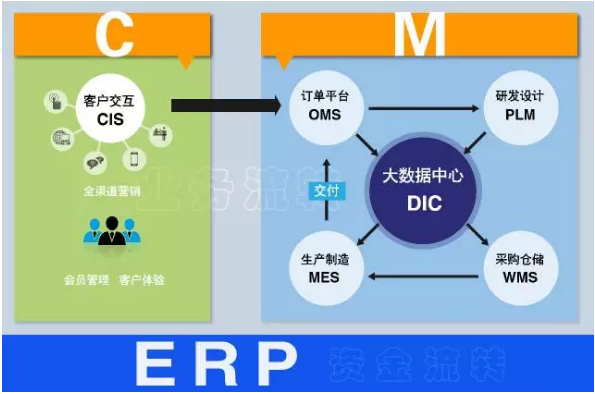

For a personalized customization company (C2M customization), from order to delivery, the following manufacturing capabilities and software system matching are required:

1. Marketing layer (CRM: member management, customer experience; omni-channel marketing: e-commerce platform, micro-commerce, stores, dealers, etc.), providing various software entrances to realize interaction with customers to obtain orders.

2. Order platform (B2B bulk orders, dealer orders, C2M orders), to achieve unified entrance and standardized management of all orders.

3. PLM product R & D management, integrating CAD, CAE and other tool software with enterprise R & D knowledge base and project management.

4. Data Intelligence Center, the collection and application of various types of data such as product design, production, quality, management and service of enterprises.

5. ERP (finance, SCM supply chain), which transforms the business activities of the enterprise into a statement of funds.

6. Intelligent manufacturing (APS, MES, CAPP, etc., centralized control center, DNC, PLC, Internet of Things, automated production line / equipment, etc.).

7. Intelligent warehousing logistics to ensure the response speed of the supply chain to ensure the stable operation of intelligent manufacturing.

About us

About us- Tel: +86-510- 85868879

- E-mail: sales@siciauto.com

- Address: No.132-4, Rongyu Road, Xishan Economic Development Zone, Wuxi City, Jiangsu Province, China.

- SUPPLIER

- PROJECTS

Wuxi Sici Auto Co., Ltd. Boxmedia