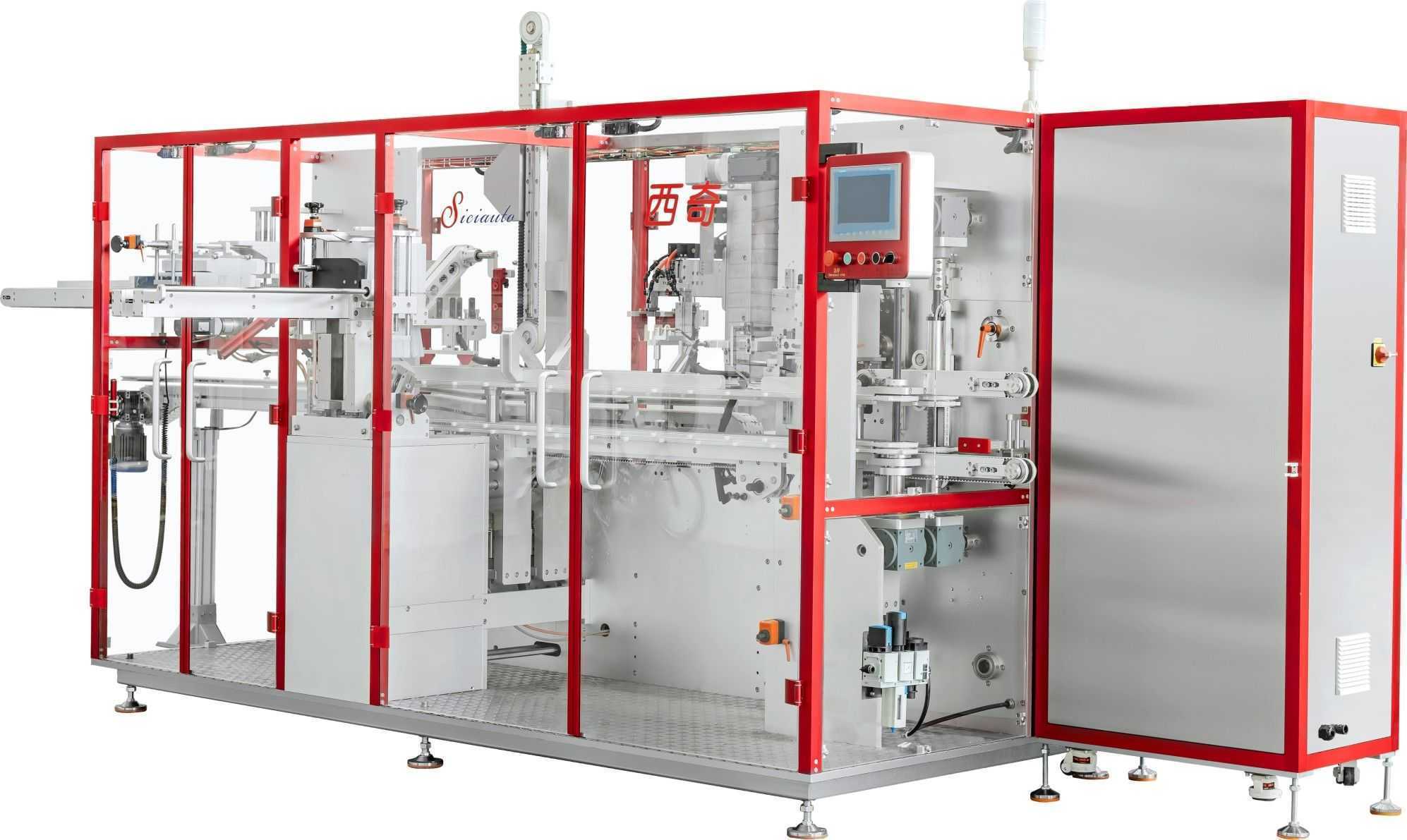

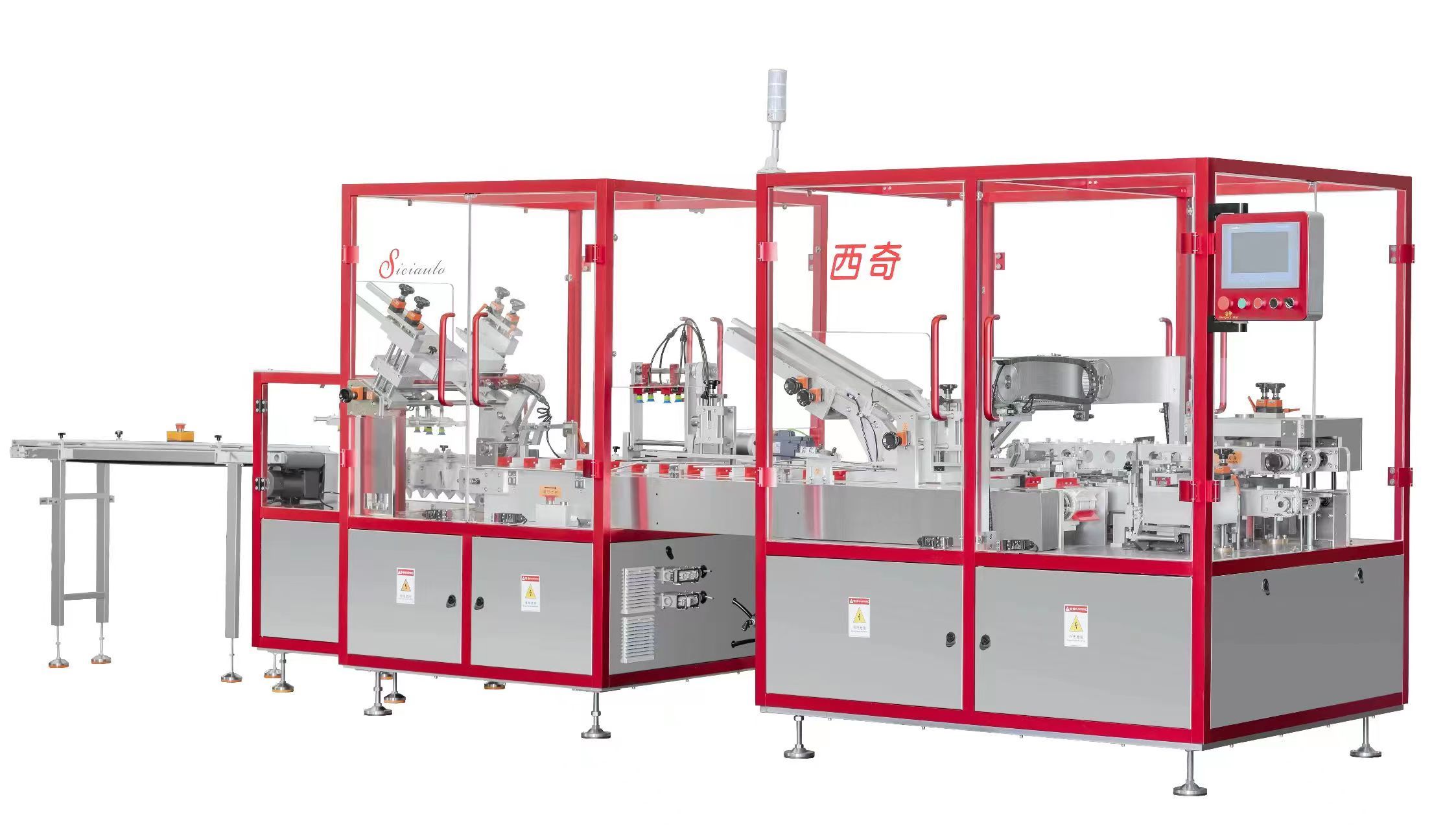

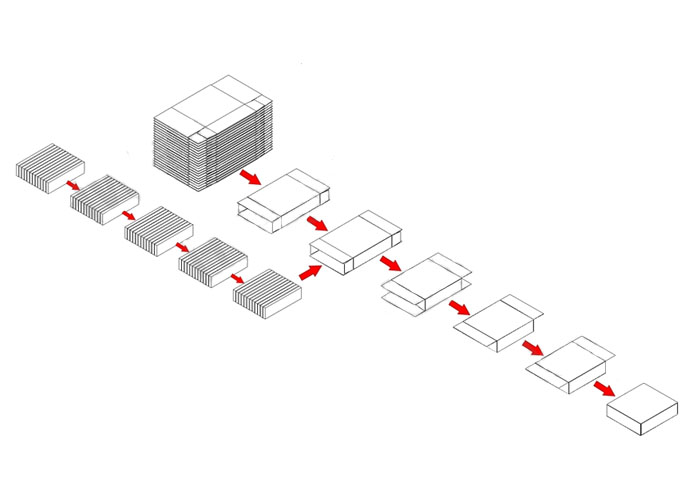

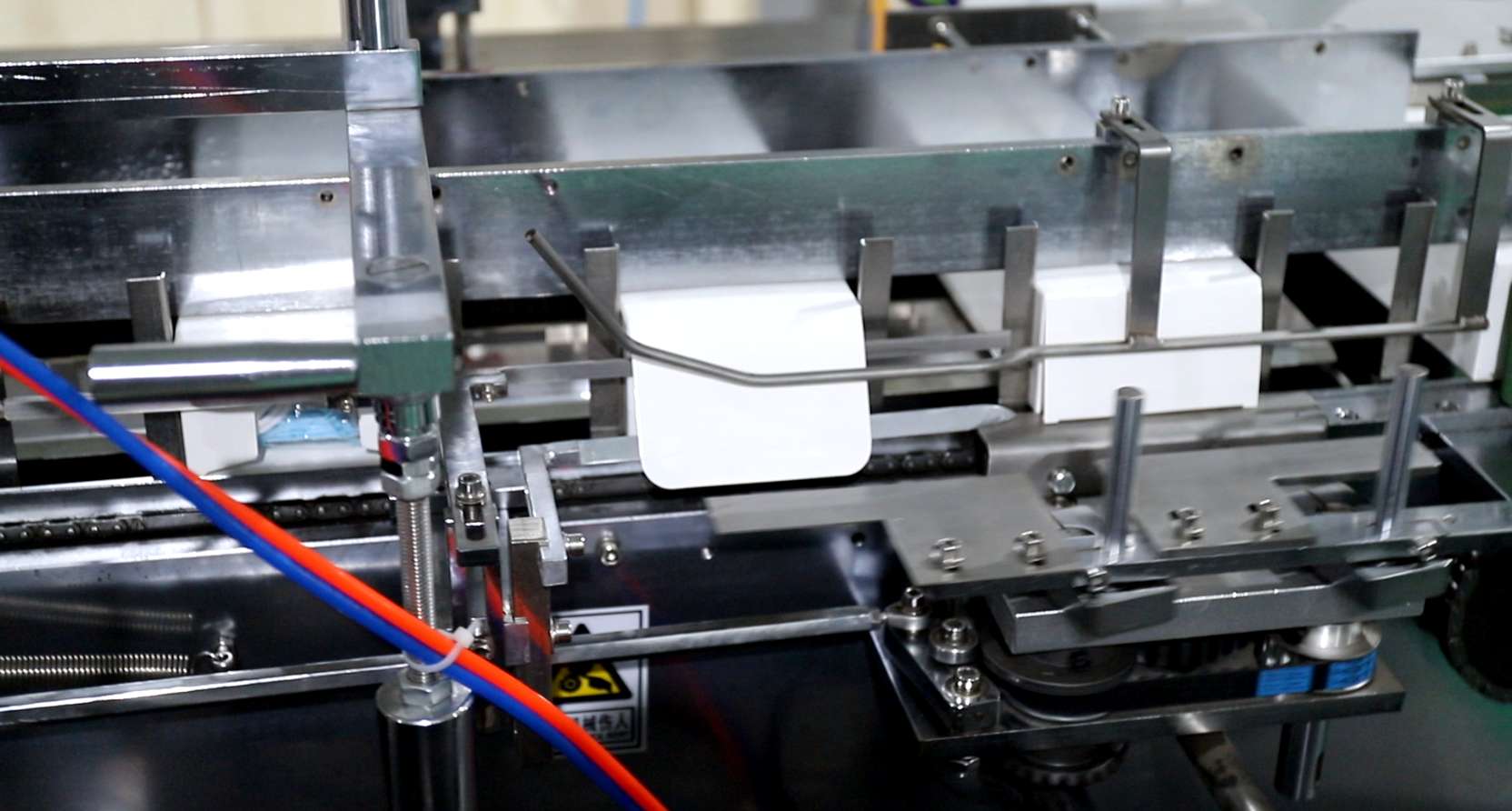

It is a kind of horizontal cartoning machine which form a carton board blank into a carton filled with a product or bag of products or number of products say into single carton, after the filling, the machine engages its tabs / slots to apply adhesive and close both the ends of carton completely sealing the carton.

The automatic cartoning machine manufactured by SICIAUTO picks a single piece from a stack of folded cartons. Further, it fills it with the product or multiple products in a horizontal direction through the open end and seals the flaps of the carton by tucking an end flap of the carton or putting on glue or adhesive.

| Model | XQ-ZH100 | |

| Speed | 50-100pcs/min | |

| Carton | Quality Requirement | 250-350g/㎡ |

Size range (L×W×H) | (55-200)mm×(30-175)mm×(14-60)mm | |

| Leaflet | Quality Requirement | 50-65g/m² |

Unfolded Size range(L×W) | (80-300)㎜×(70-210)mm | |

Fold Size range(1-4 page) (L×W) | (70-210)㎜×(20-40)mm | |

| Compressed Air | Working Pressure | 0.5-0.7mpa |

| Consumption | 15-20m³/h | |

| Voltage | 380V 50Hz | |

| Power | 1.5kw | |

| Noise | <85dB | |

MACHINE PRINCIPLE

FUNCTION & FEATURES

1. The manual is used to automatically fold the paper into the box, feeding, opening, loading, box sealing, etc. The structure is compact and reasonable, and the operation and adjustment are simple.

2. Servo / stepping motor, touch screen and PLC programmable control system are adopted to make the display operation of the interface clearer and more convenient, with high degree of automation and more humane.

3. Using automatic photoelectric detection and tracking system, box can not be placed without sensing the product, saving packaging materials to the greatest extent.

4. Large range of packaging, easy adjustment, fast conversion between various sizes

5. Usually, it is not necessary to change the mold to change the sizes.

6. It adopts automatic stop and overload protection device for the main drive motor when the articles are not in place, which is more safe and reliable.

7. According to customer requirements, a flip-up safety cover is adopted for easy operation and nice appearance.

8.It can realize linkage production with pillow packing machine, cellophane wrapping machine, bottling line, filling machine, labeling machine, laser marking printer, check weigher, other production lines and other equipment.

9. Various automatic feeders and cartoning systems can be customized according to the requirements of packaging materials.

10. Hot melt glue machine can be selected according to customer requirements, using hot melt glue spray glue seal box and mechanical brush glue seal box.

11. Fully intelligent touch screen, microcomputer to control the packaging process, simple operation and easy to understand control of mechanical equipment and production process, high reliability, fast operation speed.

12. The machine body is made by 304, 316 stainless steel , higher durability.

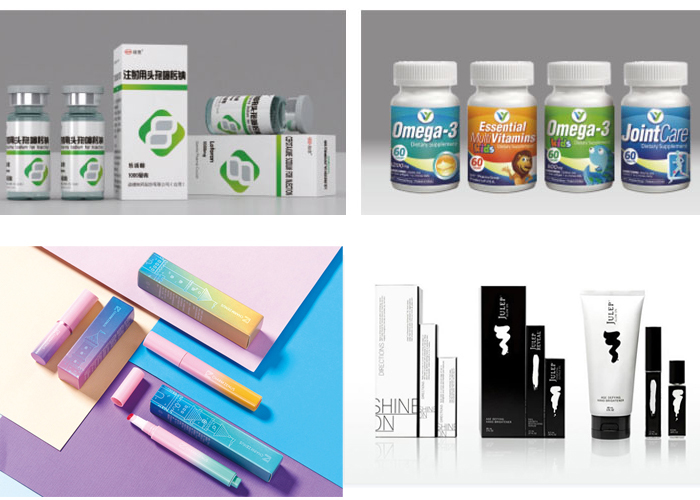

Samples

PACKAGING & SHIPPING

PACKAGING

Film wrapped inside and standard export carton packing outside.

SHIPPING

30 working days after confirming order and receive the deposit.

specific delivery date should be decided according to production season and order quantity.