- Home

- About Us

- Workflow

- Projects

- Customer Feedback

- Private Policy

- Products

- Overwrapping Machine

- Cartoning Machine

- Case Packer

- Labeling Machine

- Shrink Wrapping Machine

- Case Erector

- Case Sealer

- Check Weigher

- Strapping Machine

- All-side Ironing Machine

- Tea Bag Packing Machine

- Packaging Materials

- Pillow Type Packing Machine

- Filling And Capping Machine

- Tube Sealing Machine

- Solutions

What is the future of packaging automation?2021-11-26Packaging is essential in today's business world, which has prompted manufacturers to find the best solutions to meet customer needs. The latest Industry 4.0 technology enables manufacturers to further realize the digitization of production, making customers feel more connected in all aspects. Here, Neil Bellinger, head of EU Automation EMEA, a supplier of automation components, discussed three major innovations in the field of packaging automation that will help manufacturers remain competitive and optimize their production.

According to data from 4.0 Research, Industry 4.0 has developed at an alarming rate in recent years and is expected to reach US$1 trillion by the beginning of 2030. This technological advancement is an excellent opportunity for manufacturers in the packaging industry to accelerate their digital strategy and respond to customer needs in an effective manner.

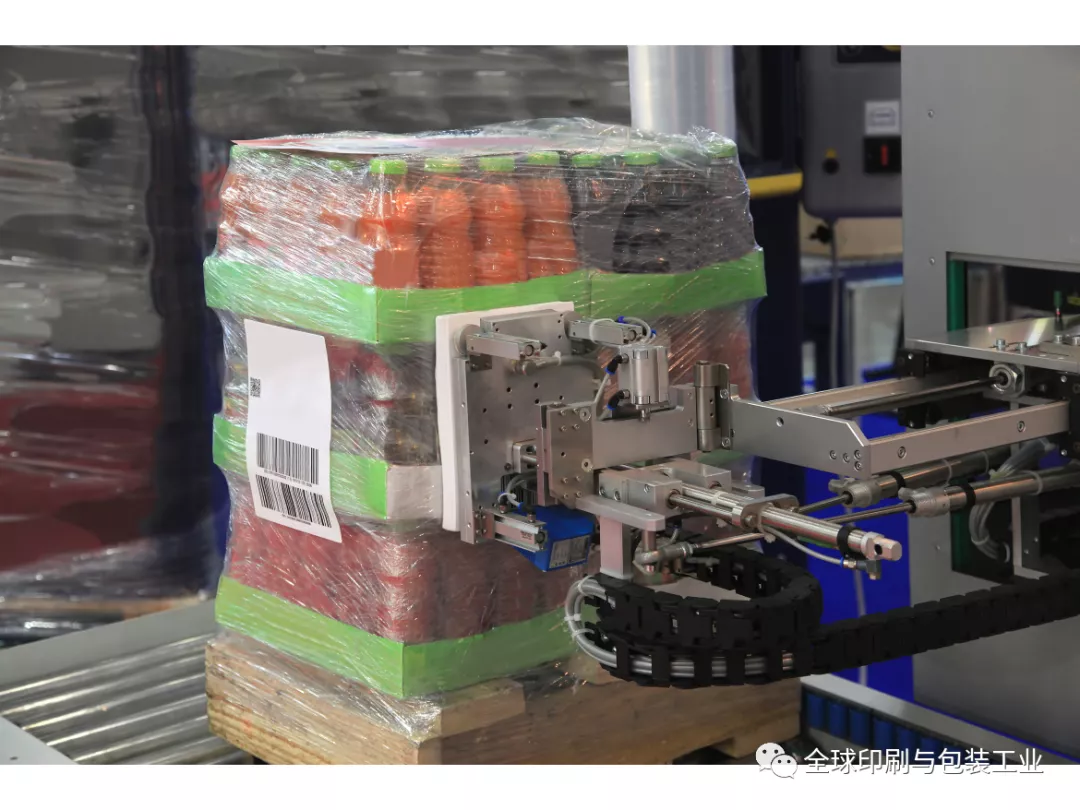

01 Robot palletizing

Palletizing requires repeated lifting of heavy objects and is tiring for human workers. The use of automation technology can become more efficient. For example, collaborative robot arms can be easily programmed and redeployed according to tasks, and workflows can be optimized, especially during peak seasons. They are also cost-effective, ensuring a quick return on investment, and without the need for additional costs for programming and dedicated work units. This also means that manufacturers can implement multiple collaborative robot arms during the palletizing process to speed up production and loading of multiple products.

Collaborative robotic arms can be used for packaging applications in all major industries, from pharmaceuticals to electronics or metal processing, but also for food and beverages. They can also handle delicate products. For example, Universal Robots UR10 has a payload of up to 10 kg, but it can also palletize small and fragile products such as eggs. The robot has a compact design, weighs 28.9 kg, and covers an area of only 190 mm, ensuring flexible packaging in an industry where reliability and precision are paramount.

02 Smart packaging

In the 2019 Clean Label Report, the world’s leading nutrition company Kerry Group found that customers are increasingly questioning label claims. 49% of the respondents believe that there is not enough packaging information to help them take care of their lifestyle. Make a wise decision.

In supermarkets, few customers spend time reading labels carefully. In addition, labels are sometimes torn or erased, or are incomplete. Smart packaging allows shoppers to use their devices to gain deeper exposure to their products. This is where the Internet of Things comes into play.

Smart products are assigned IDs that can help customers in different ways. For example, they can use a near field communication (NFC) tag equipped with a temperature sensor to check whether the product has been stored at the right temperature. NFC tags are passive devices, they operate without their own power source, and rely on active devices to enter range before being activated. This means that customers only need to touch the package with an NFC-enabled mobile phone to collect useful information.

Whisky company Johnnie Walker is currently using NFC technology to allow customers to check whether the bottle has been tampered with and whether it is properly sealed. Likewise, customers can get "before-use" warnings, real-time quotes, or they can use digitally stored data to track the journey of products throughout the supply chain.

03 Flexible motion control

The packaging must not only be interactive, but must also meet the customer's requirements and tastes. The focus is no longer on mass production, but on mass customization. For example, bottled water used to be a single unit, but now it can appear in packs of six, twelve or even twenty bottles. The manufacturer may produce six packs a day and twelve packs another day. This means that packaging equipment needs to be programmed to change quickly and frequently.

The motion control system is designed to handle rapid replacement and add additional functions to provide a more flexible process. One of the strategies to achieve this goal is flexible programming, which means being able to use different codes on the same controller. Smart machines can create set points, allowing a single machine to run the first product at a programmed speed and use different tools to set functions and run products with different characteristics.

Yaskawa has developed a single control architecture that can control hybrid sports equipment, including six-axis joint robots. This increases the flexibility of the packaging and reduces programming, thereby making the replacement operation faster. From increasing speed to making customers feel better in control of their choices, automation technology is evolving along with packaging trends. To ensure that they respond to customer needs, manufacturers need to keep up with innovative technologies and digital trends.

About us- Tel: +86-510- 85868879

- E-mail: sales@siciauto.com

- Address: No.132-4, Rongyu Road, Xishan Economic Development Zone, Wuxi City, Jiangsu Province, China.

- SUPPLIER

- PROJECTS

Wuxi Sici Auto Co., Ltd. Boxmedia