- Home

- About Us

- Workflow

- Projects

- Customer Feedback

- Private Policy

- Products

- Overwrapping Machine

- Cartoning Machine

- Case Packer

- Labeling Machine

- Shrink Wrapping Machine

- Case Erector

- Case Sealer

- Check Weigher

- Strapping Machine

- All-side Ironing Machine

- Tea Bag Packing Machine

- Packaging Materials

- Pillow Type Packing Machine

- Filling And Capping Machine

- Tube Sealing Machine

- Solutions

Create automation brand equipment, SICIAUTO Intelligence has something to say2021-03-08

"Intelligent Automation" has become SICIAUTO's strong competitiveness.

Whether it is Germany’s “Industry 4.0”, the US’s “Industrial Internet Project”, Japan’s “Super Smart Blueprint 5.0”, or the transformation and upgrading of China’s industrial manufacturing, in recent years, the industry is moving towards intelligent automated production, packaging equipment in the cosmetics industry The same is true for production.

SICIAUTO Intelligent Technology Co., Ltd. (hereinafter referred to as "SICIAUTO") has also been dedicated to the production of complete automatic packaging equipment for cosmetics for 16 years.

Strong innovative elite team

Research and development of "hard core" equipment

As we all know, the most difficult thing for equipment R&D factories is technological innovation. Good equipment often has the effect of "doubling the effort with half the effort" for product production.

SICIAUTO has 16 years of production line experience in the cosmetics, pharmaceuticals, and food fields, and its automated equipment production R&D team is a strong brand endorsement.

The R&D team is composed of 8 outstanding design engineers, 6 first-class mechanical engineers in the automation industry, 2 electrical engineers, and 5 whole-line commissioning engineers.

Under the linkage of the clear cosmetics production business line and the pharmaceutical production line business department, using Italian technology, innovation and integration of domestic product differentiation, the automatic tray boxing machine developed can cleverly realize one-click switching of cosmetics with or without internal support. To meet the diverse needs of product packaging, it is the first in the domestic cosmetics equipment research and development industry.

At the same time, the rise of the "value economy", especially female consumers, has extended diversified needs for cosmetics for their unique appearance, practicality, convenience, and sustainable development. The search index for the words "good-looking, practical, and environmentally friendly" is rising. .

A reporter from China Beauty Network learned that this year, the one-piece wrapping machine newly developed by SICIAUTO engineers maintains the product’s flat and delicate packaging appearance. It uses hot-melt sealing instead of traditional sealing tape and suction paper on the raw materials. , Feeding, sorting, forming and pressing can all be completed automatically, which can be described as multi-party fulfilling the needs of appearance, environmental protection, cost reduction and quality improvement, winning the favor of the market.

In the era of "wisdom"

Speak with automation

In the cosmetics industry consumption data released by the National Bureau of Statistics, the total retail sales of the cosmetics industry in 2020 is 340 billion yuan, a year-on-year increase of 9.5%, especially driven by the strong promotion of e-commerce such as Double Eleven. The number of domestic cosmetics foundry companies has also increased from more than 70 in 1980 to more than 5,000 today. Intelligent automation has also become one of the "nirvana" for factories to gain popularity.

SICIAUTO is located in Wuxi on the shore of the beautiful Taihu Lake, where more than 200 of the world's top 500 companies are gathered, and the industrial production and manufacturing atmosphere is unique.

In December last year, SICIAUTO also smoothly moved the factory from Chunhui Road to Plainvim International (Wuxi) Modern Industrial Park. Here is a collection of outstanding port machinery, metallurgical equipment, engineering machinery and automotive specialty industries, which also means Xiqi’s automated production has ushered in new opportunities for development.

In the production of cosmetics packaging, from relying on a large number of manual flow operations to now to the high-end advancement brought by semi-automatic or fully automatic equipment, the level of intelligent automation has become the trump weapon for testing the strength of the factory.

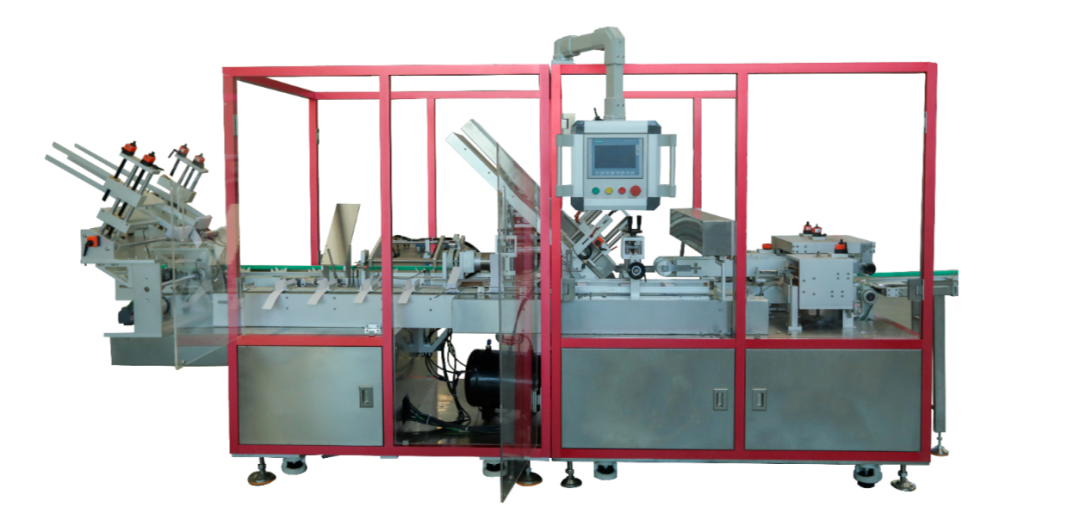

▴ Fully automatic pallet cartoning machine

In terms of automation performance, SICIAUTO has a one-piece wrapping and packaging machine, a box filling machine with an inner tray, a weighing and rejecting machine, a labeling and printing machine, a cigarette packer, a visual inspection and rejecting machine, a fully automatic opening, packaging and sealing machine and a robot Palletizing, etc., covers cosmetics-related packaging categories such as facial masks, skin care, and color cosmetics.

In addition, in the production process, SICIAUTO adopts a product traceability system of "one item, one code". As long as the staff scan the package, they can understand the specific information of the product, and create a strong traceability strength for product management and information inquiries.

Customer-centric

Obtained a number of patents

Continuing the continuous tracing of the intelligent automation of packaging equipment, Xiqi has been active in the field of cosmetic packaging in the form of "consultant" services for many years, providing customized and automated products for corporate brands such as Jialan, Yunifang, Leaf Spring, and Kazilan. Packing the whole line equipment.

In line with the "ingenuity creation" of automatic packaging equipment, Xiqi has also obtained as many as 40 practical patent certificates, such as unpacking and packing all-in-one machine, automatic cartoning machine, automatic three-dimensional cigarette pack, etc., and obtained "China Beauty Industry Awards" has multiple awards.

In order to promote the deepening of the market for Sic packaging production equipment, the founder Wang Mao established Sic International Trading Co., Ltd. and Wuxi Dyke Packaging Technology Co., Ltd. to sell to the United States, Spain, Italy, New Zealand, Thailand and other countries around the world. Packaging production line and packaging equipment.

Not only that, Xiqi is committed to the research and development in the field of cosmetics automated packaging, co-creating R&D technical cooperation with Jiangnan University, a well-known 211, 985 college, and setting up an office in Xicheng Industrial Zone, Renhe Town, Baiyun District, Guangzhou, constantly seeking to create intelligence Technology and automation will bring more hard-core equipment and advanced smart factories to the cosmetics packaging industry.

And there is no doubt that with the opening and upgrading of industrial technology, on the road of cosmetic production line packaging, intelligent automated unmanned production will definitely bloom its unique brilliance and charm, and undergo major changes in the pattern.

About us- Tel: +86-510- 85868879

- E-mail: sales@siciauto.com

- Address: No.132-4, Rongyu Road, Xishan Economic Development Zone, Wuxi City, Jiangsu Province, China.

- SUPPLIER

- PROJECTS

Wuxi Sici Auto Co., Ltd. Boxmedia